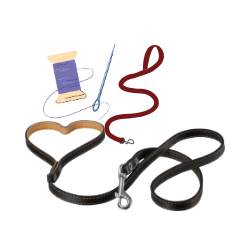

Dog leashes are typically made from strong, durable materials designed to withstand the stress of walking or controlling a dog. Here’s a general overview of the steps involved in making a dog leash:

1. Material Selection

- Fabric Leashes: Many leashes are made from nylon or polyester, which are strong, flexible, and resistant to wear and tear. Some may also be made from cotton or leather.

- Leather Leashes: Leather leashes are often made from high-quality leather, typically cowhide, which is processed to be both strong and flexible.

- Chain Leashes: Some leashes are made from metal chains, often used for larger or stronger dogs.

- Rope Leashes: These are made from thick, sturdy ropes, sometimes braided for extra strength.

2. Cutting the Material

- The selected material (nylon, leather, etc.) is cut to the desired length. The typical leash length ranges from 4 to 8 feet, but it can be customized.

3. Stitching and Reinforcement (For Fabric Leashes)

- If the leash is made from fabric (like nylon), the material is often folded over and stitched for durability. This stitching can be reinforced with additional layers or threads for added strength.

4. Adding Hardware

- Clips/Carabiners: The end of the leash is attached to a metal clip, usually made from steel or aluminum, which allows the leash to be securely attached to a dog’s collar or harness. The clip can be a trigger-style clip, snap hook, or carabiner.

- D-Ring: Some leashes have a D-ring near the handle for attaching waste bags or other accessories.

5. Handle Creation

- For fabric leashes, a loop handle is sewn into the opposite end of the leash. This is usually padded with a soft material (like neoprene or foam) for comfort.

- Leather leashes may have a handle that’s simply a loop or a thicker portion of leather for easier grip.

- The handle is usually reinforced with stitching to prevent fraying and ensure it can support pulling.

6. Finishing Touches

- Edge Sealing (Fabric Leashes): The edges of fabric leashes may be sealed or hemmed to prevent fraying.

- Burning Ends (Rope Leashes): The ends of nylon or other synthetic rope leashes may be melted with heat to prevent them from unraveling.

- Polishing (Leather Leashes): Leather leashes may be polished or treated with oils and conditioners to keep the material supple and protect it from damage.

7. Quality Control

- The leash is inspected for defects such as loose stitching, weak spots, or misaligned hardware. This ensures the leash is durable and safe for use.

Once all these steps are completed, the leash is ready for packaging and sale!

Leave a Reply